Loading docks are bustling hubs in warehouses and distribution centers – but they’re also among the most dangerous areas without proper precautions. Roughly 25% of all warehouse injuries occur at loading docks, and for every actual injury, there are about 600 near-miss incidents. These accidents are not just statistics: between 2015 and 2020, some 33,000 employees missed work due to loading dock injuries, and dozens of workers lost their lives.

Whether it’s a forklift backing off an open dock or a worker slipping on a slick floor, the consequences can be severe. The good news is that most loading dock accidents are preventable with the right safety measures in place. In this article, we’ll explore the top five loading dock safety hazards and how to prevent each of them, helping you keep your team safe while maintaining efficient operations.

Hazard #1: Falls from the Loading Dock Edge

Falls from loading dock edges are one of the most common and dangerous hazards. A drop of four feet or more can cause serious injuries if a worker or forklift slips or rolls off. Open doors without trailers or inattention near dock edges are major risk points.

How to Prevent It:

- Install dock swing gates, safety dock gates, or dock barricades to block exposed edges. OSHA requires protection on docks with drops over four feet.

- Use visual dock warning barriers like chains or foldable gates when doors are open but no trailer is present.

- Mark edges and post signage with reflective tape or warning signs to alert workers.

- Train and enforce rules through regular safety talks and written procedures, ensuring gates are used properly. Include guidelines from your facility’s dock safety guide.

Hazard #2: Trailer Creep and Early Departure

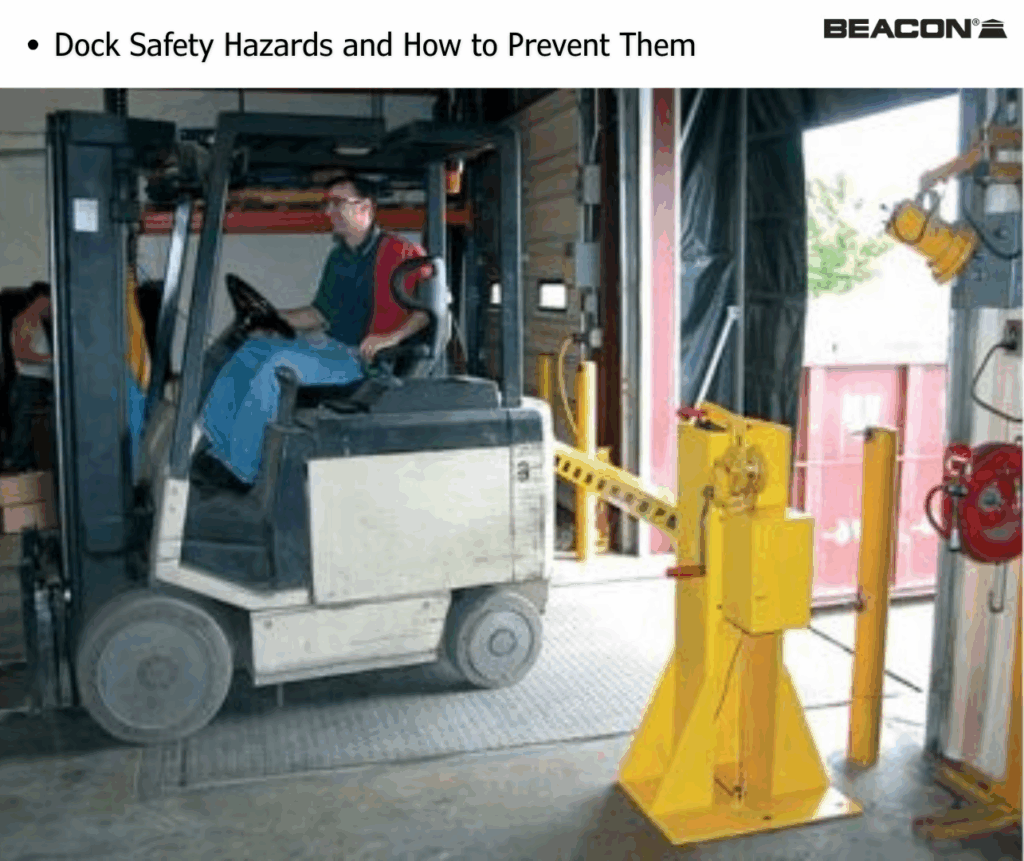

Trailer creep happens when a trailer moves away from the dock, and early departure occurs when a truck pulls out before loading is complete. Both can cause forklifts to fall or tip, risking injuries and damage.

How to Prevent It:

- Use Wheel Chocks or Truck Restraints every time. Automated locks offer stronger security than manual chocks.

- Install a wheel loading guide to keep trailers aligned, reducing drift.

- Employ signal lights for clear communication between dock staff and drivers.

- Set strict procedures that include checklists, key control, and verified communication before trucks depart.

Hazard #3: Struck-by Accidents (Forklifts and Trucks)

Docks are busy with forklifts and trucks, which raises the risk of pedestrian injuries. Limited visibility, tight spaces, and human error contribute to struck-by incidents.

How to Prevent It:

- Limit pedestrian access to active dock zones and create safe walkways.

- Improve visibility with lighting, high-visibility vests, and forklift warning lights.

- Install barriers and overhead door guides to separate people from vehicle paths.

- Train everyone on traffic rules, including safe distances, right-of-way, and communication protocols.

- Coordinate truck movements with spotters and enforce safe backing practices.

Hazard #4: Slips, Trips, and Environmental Dangers

Weather, spills, and poor housekeeping make docks slippery and hazardous. Even small debris or water buildup can lead to falls, especially when carrying heavy items.

How to Prevent It:

- Keep floors clean and dry with regular sweeping, spill response kits, and snow/ice removal.

- Improve traction using non-slip mats, coatings, or gritted surfaces.

- Ensure proper lighting in all areas, especially trailer interiors and dock corners.

- Use seals and ventilation to block weather and manage air quality.

- Require proper footwear to reduce slipping on wet or oily surfaces.

Hazard #5: Equipment and Structural Failures

Malfunctioning dock levelers, overhead doors, or outdated equipment can lead to falls, strikes, and load collapse. Without maintenance and protection, even small mistakes can cause large-scale accidents.

How to Prevent It:

- Schedule regular maintenance for dock plates, doors, and lifts to detect issues early.

- Upgrade old equipment with modern systems featuring built-in safety features.

- Install protective guards like dock door protectors, bumpers, and bollards to absorb impacts.

- Use loading safety devices such as trailer stands, safety lips, and control sensors.

- Train staff thoroughly in equipment use, maintenance, reporting, and emergency protocols.

Take a look at one of Beacon’s testing Dock Board and Dock Leveler Safety.

Loading docks will always be busy, dynamic places – but they don’t have to be dangerous. By being aware of these top five hazard areas (falls, trailer separation, vehicle collisions, slips, and equipment failures) and proactively addressing each one, you can create a much safer loading dock environment. The common thread in prevention is a combination of the right equipment (physical safety devices), the right procedures (clear rules and training), and constant vigilance. Most loading dock accidents, from forklift fall-throughs to simple slips, share a common truth: they are largely preventable with foresight and good practices.

For U.S. businesses, compliance with OSHA standards is the baseline, but truly effective dock safety goes beyond mere compliance – it’s about fostering a culture where everyone from managers to forklift drivers takes safety seriously. Encourage your team to speak up about hazards, follow a loading dock safety guide or checklist daily, and never cut corners when it comes to securing trailers or wearing PPE. Small actions like cleaning up a spill immediately or double-checking a wheel chock can be the difference that prevents an injury.

In the end, maintaining a safe loading dock is not just about avoiding fines or injuries (important as those are), but also about efficiency and morale. Workers who feel safe will be more confident and productive, and operations will run more smoothly without the disruptions caused by accidents. So take a thorough look at your loading dock with these hazards in mind, and address any gaps in safety measures. By implementing the prevention strategies outlined above – from dock barricades and swing gates to training on forklift etiquette – you’ll be well on your way to an injury-free, well-run loading dock. Remember, safety is an investment that always pays off, in every saved life, avoided injury, and uninterrupted day of work. Keep your loading docks safe, and you’ll keep your business moving in the right direction.

Browse 10 Products

Browse 10 Products