Value added for standard or design to build core products is Beacon’s main business model in the material handling industry Beacon provides some of the widest selections of standard and sophisticated products on the market today, working and supplying some of the latest material handling solutions in major industry circles. Working with many worldwide governments […]

Read More

Barriers – Practicing CDC Guidelines

Beacon is focused on providing industrial and crowd control barriers to help minimize the spread of the Coronavirus Disease (Covid-19).

Read More

Read More

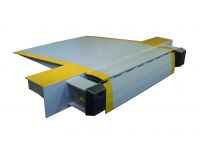

Air Bag Dock Leveler vs Mechanical Dock Leveler

Beacon now offers the air bag leveler to be competitive on the market today. BXA Air Bag Dock Levelers offers some of the same advantages as the spring actuated mechanical dock levelers but with a cost savings.

Read More

Read More

Dock Board and Dock Leveler Safety

Dock boards and dock levelers are one of many key elements for loading dock safety. Loading dock safety is paramount at any loading dock area. OSHA Standard – 29 CFR 1910.30(a) Dockboards (bridge plates). ANSI – American National Standards Institute, is responsible for the safety, performance and testing of Dock Leveling Devices. MH30.1 – 2007, […]

Read More

Read More

Guard Rails vs. Bollards

At job sites and facilities with a high amount of traffic from forklifts, vehicles and other mobile equipment, it is important to provide a safe working environment in areas near these heavy, fast moving pieces of machinery.

Read More

Read More

Dock Levelers vs. Yard Ramps

Across the United States, businesses are designing their loading and unloading procedures in a number of different ways.

Read More

Read More

Dock Signal Lights vs. Loading Dock Spotlight

Loading docks are one of the many fast paced and injury prone working environments at manufacturing and storage facilities across the globe.

Read More

Read More

Cable Cover Ramps Guard

According to OSHA, slips, trips and falls make up the majority of general industry accidents, as well as 15 percent of all accidental deaths. Part of the organization’s 1910.22(b)(1) standard states that “aisles and passageways shall be kept clear and in good repairs, with no obstruction across or in aisles that could create a hazard.” […]

Read More

Read More

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 11 Products

Browse 11 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products