A practical guide for safer, more efficient loading dock operations

Introduction

Loading docks are among the busiest and most hazardous areas in warehouses, manufacturing plants and distribution centers. Industry studies consistently show that a significant percentage of warehouse injuries occur at the dock, with hundreds of near miss incidents for every reported injury. Falls, trailer movement, vehicle strikes, slips and equipment failures can all lead to serious injuries, lost productivity and costly workers’ compensation claims.

The encouraging reality is that most loading dock accidents are preventable. With the right combination of equipment, procedures and training, facilities can dramatically reduce risk while keeping operations moving efficiently. This guide outlines the top five loading dock safety hazards and proven strategies to prevent them.

Hazard #1: Falls from the Loading Dock Edge

Open dock edges present one of the most severe risks. A fall of four feet or more from a dock edge or into an empty trailer bay can cause serious injury or worse. These incidents often occur when dock doors are open without a trailer present or when edge protection is not used consistently. Roughly 25% of all warehouse injuries occur at loading docks, and for every actual injury, there are about 600 near-miss incidents. A 2021 Department of Labor Office of Inspector General report showed warehouse-related injuries nearly doubled, from around 42,500 to over 80,500 cases.

How to Prevent It

- Install dock safety gates, swing gates, or barricades to block exposed edges.

- Use visual dock barriers such as chains or fold down guards when doors are open but unattended.

- Clearly mark dock edges with high visibility paint, reflective tape and warning signage.

- Establish written procedures requiring edge protection whenever a dock door is open.

- Reinforce proper use through regular safety meetings and audits.

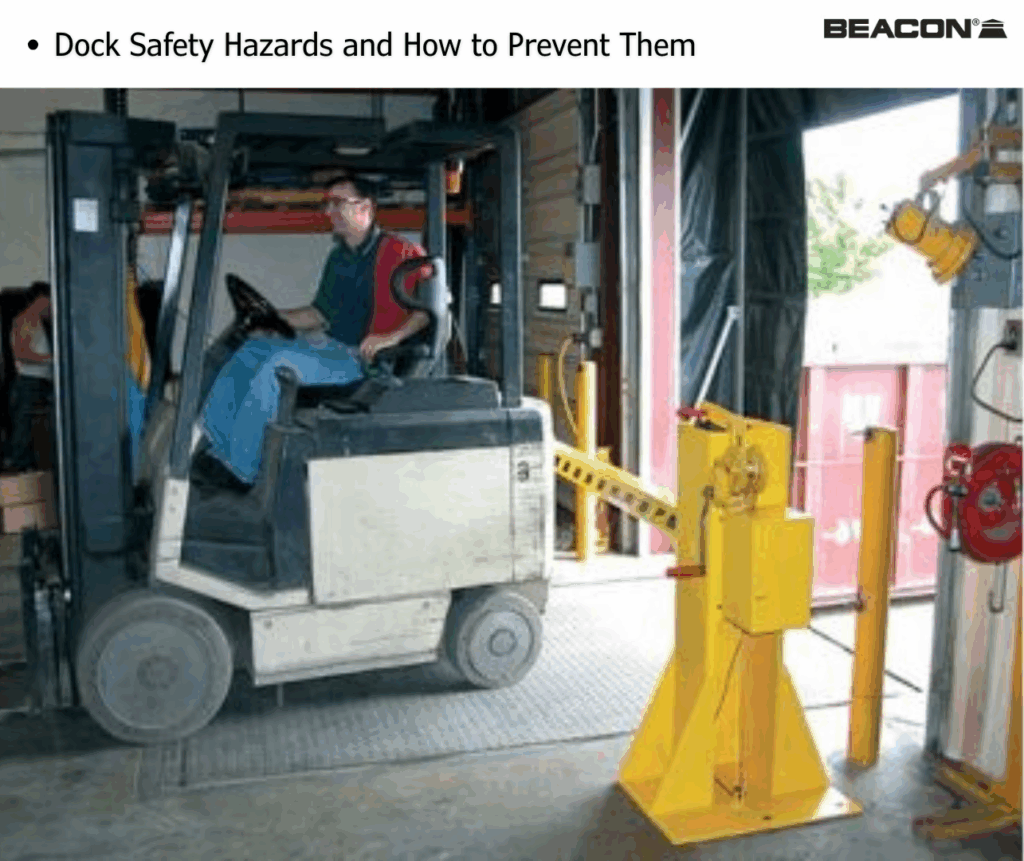

Hazard #2: Trailer Creep and Early Departure

Trailer creep occurs when a trailer gradually moves away from the dock during loading. Early departure happens when a driver pulls away before loading is complete. Both scenarios can cause forklifts to fall between the dock and trailer, leading to severe injuries and equipment damage.

How to Prevent It

- Use wheel chocks or truck restraints on every load. Automated restraints provide the highest level of security.

- Install wheel guides to keep trailers properly aligned with the dock.

- Use dock signal lights to clearly communicate safe and unsafe conditions to drivers.

- Implement strict departure procedures, including checklists, key control and verified communication before release.

Hazard #3: Struck-By Accidents (Forklifts and Trucks)

Loading docks are high traffic zones where forklifts, pallet jacks, and trucks operate in tight spaces. Limited visibility and mixed pedestrian traffic increase the risk of struck-by incidents.

How to Prevent It

- Restrict pedestrian access to active dock areas and establish clearly marked walkways.

- Improve visibility with adequate lighting, mirrors and high-visibility apparel.

- Install barriers, bollards and overhead door guides to separate people from vehicle paths.

- Train all personnel on traffic rules, right of way and communication protocols.

- Coordinate truck movements using spotters and enforce safe backing procedures.

Hazard #4: Slips, Trips, and Environmental Hazards

Water, oil, debris, snow and ice can quickly turn dock floors into slip hazards. Poor lighting and clutter further increase the risk, especially when workers are carrying loads.

How to Prevent It

- Maintain clean, dry floors with regular housekeeping and spill response procedures.

- Improve traction using non slip mats, coatings, or textured surfaces.

- Ensure consistent lighting in dock areas, trailers and corners.

- Use dock seals, shelters and ventilation to manage weather exposure and air quality.

- Require appropriate slip resistant footwear for dock personnel.

Hazard #5: Equipment and Structural Failures

Worn or malfunctioning dock levelers, dock plates, overhead doors and lifts can fail unexpectedly, causing falls, load collapse, or struck-by incidents.

How to Prevent It

- Schedule routine inspections and preventive maintenance for all dock equipment.

- Upgrade outdated systems with modern equipment featuring built in safety devices.

- Install protective guards, bumpers and bollards to reduce impact damage.

- Use additional safety devices such as trailer stands, safety lips and control sensors.

- Train employees on proper equipment operation, reporting procedures and emergency response.

Building a Safer Loading Dock

Loading docks will always be fast paced, dynamic environments but they do not have to be dangerous. Falls, trailer separation, vehicle collisions, slips and equipment failures share a common truth: they are largely preventable.

Effective dock safety relies on three core elements:

- The right equipment – physical safety devices that control hazards

- The right procedures – clear rules, checklists and communication

- Ongoing vigilance – training, inspections and a culture that prioritizes safety

While regulatory compliance sets the baseline, the safest facilities go further by encouraging employees to speak up, follow daily safety checklists and never cut corners. Small actions like securing a trailer or cleaning a spill immediately can prevent serious injuries.

Final Takeaway

A safe loading dock protects people, equipment and productivity. Workers who feel secure are more confident and efficient and operations run more smoothly without costly disruptions. By addressing these five common hazards and implementing proven prevention strategies, facilities can create a safer, more reliable loading dock environment one that keeps both people and business moving forward.

Always verify that safety equipment and procedures are suitable for your specific application and operating conditions.

Browse 38 Products

Browse 38 Products